CNC precision machining has become a cornerstone of modern industrial prototyping, providing unparalleled accuracy, speed, and versatility. As industries move toward more complex and custom designs, the ability to produce high-quality prototypes efficiently has become critical. This technology not only enhances manufacturing workflows but also allows engineers and designers to test and refine their concepts before committing to full-scale production.

Understanding CNC Precision Machining

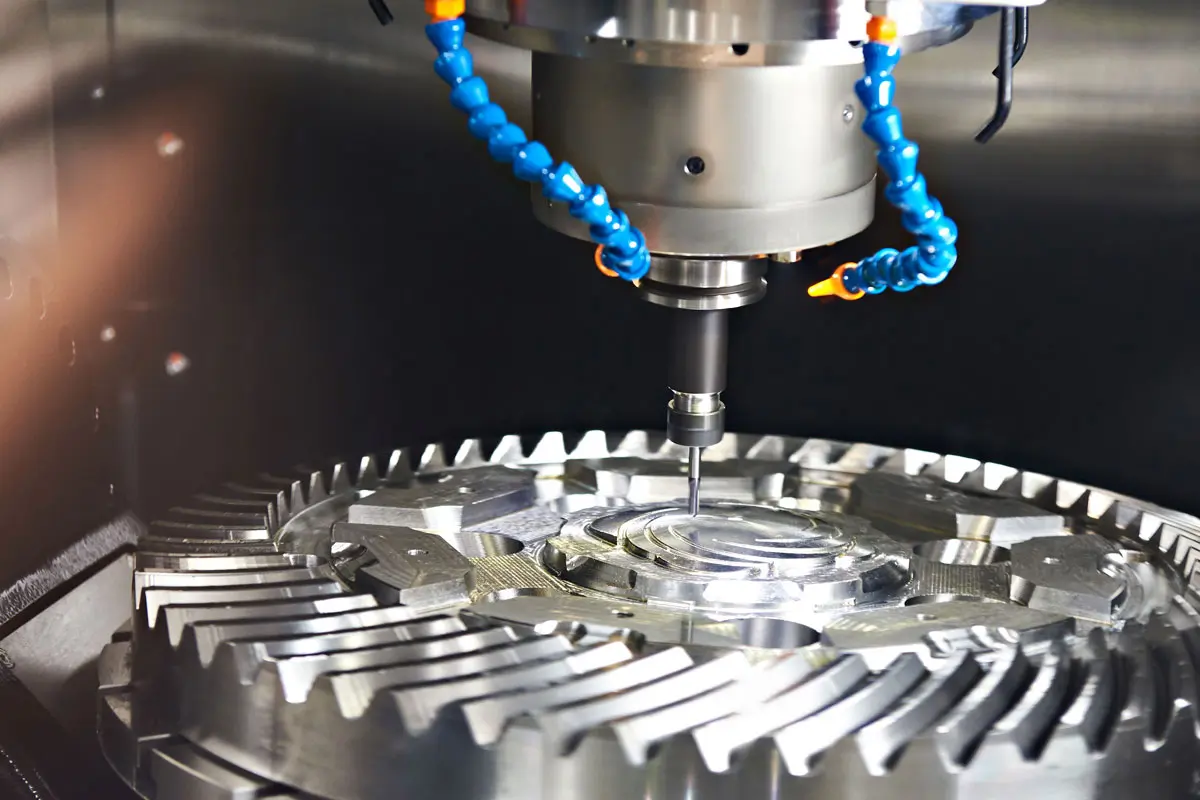

CNC, or Computer Numerical Control, precision machining is a manufacturing process in which computer-controlled machines shape and cut materials into precise components. Unlike traditional manual machining, CNC technology allows for consistent replication of complex designs with minimal human error. Materials such as metals, plastics, and composites can be processed to tight tolerances, making it ideal for industrial prototyping where precision is paramount.

The process involves the use of sophisticated software to control machine tools, including lathes, mills, and routers. The software interprets digital design files, typically created in CAD (Computer-Aided Design), and converts them into instructions for the CNC machines. This enables the production of intricate geometries and fine details that would be challenging or impossible with manual techniques.

Advantages for Industrial Prototyping

CNC precision machining offers numerous advantages for industrial prototyping. One of the primary benefits is speed. Rapid prototyping is crucial in today’s competitive environment, and CNC machines can produce prototypes quickly while maintaining high accuracy. This accelerates product development cycles and reduces time-to-market.

Another advantage is repeatability. Prototypes often require multiple iterations to optimize design, and CNC precision machining ensures that each iteration is consistent with the previous one. This consistency is essential for testing, as even minor variations can affect performance evaluation and decision-making.

Additionally, CNC precision machining provides flexibility. Engineers can work with a wide range of materials and switch between different design iterations without extensive retooling. This capability is particularly valuable for complex industrial components that require fine tolerances and intricate features.

Material Versatility in Prototyping

Industrial prototyping demands materials that can mimic final production parts. CNC precision machining supports a broad spectrum of materials, from aluminum, stainless steel, and titanium to engineering plastics like ABS and PEEK. Each material offers unique properties, such as strength, weight, or heat resistance, allowing engineers to test prototypes under real-world conditions.

For example, aerospace components require materials that are both lightweight and durable. CNC precision machining can accurately shape titanium parts, ensuring structural integrity while maintaining strict tolerances. Similarly, automotive prototypes may use aluminum or high-performance plastics to evaluate weight reduction strategies without compromising functionality.

Enhancing Design Accuracy and Complexity

One of the most compelling aspects of CNC precision machining is its ability to handle complex geometries. Industrial prototypes often include intricate features like internal channels, thin walls, and precision threads. CNC machines can execute these designs with remarkable accuracy, enabling engineers to test detailed aspects of a prototype before full-scale production.

The technology also facilitates iterative design improvements. Engineers can modify CAD files and produce updated prototypes with minimal downtime. This rapid feedback loop helps identify potential issues early, reducing costly errors during mass production.

Cost Efficiency in Prototype Development

Although CNC precision machining requires an upfront investment in machinery and software, it can significantly reduce overall prototyping costs. Traditional methods may involve hand-fabricated parts or multiple outsourced processes, leading to delays and increased expenses. CNC machining consolidates these steps into a single, automated process, minimizing labor costs and material waste.

Furthermore, CNC precision machining reduces the need for expensive molds or tooling in the early stages of product development. Engineers can produce functional prototypes directly from digital files, testing form, fit, and function without committing to permanent tooling. This flexibility is especially beneficial for startups and small manufacturers seeking cost-effective ways to bring new products to market.

Integration with Additive Manufacturing

CNC precision machining is often used alongside additive manufacturing techniques, such as 3D printing, to enhance industrial prototyping. While 3D printing allows rapid creation of complex shapes, CNC machining provides superior surface finish, mechanical strength, and precision. Combining both methods allows engineers to leverage the strengths of each technology, creating prototypes that are both functional and highly detailed.

For instance, a prototype may be 3D printed for conceptual evaluation and then refined using CNC machining for functional testing. This hybrid approach ensures that designs are both manufacturable and optimized for performance, bridging the gap between concept and production-ready components.

Quality Control and Testing

Precision is critical in industrial prototyping, and CNC machining ensures that every prototype meets exact specifications. Advanced CNC systems include in-process monitoring and inspection capabilities, allowing engineers to verify dimensions and tolerances during manufacturing. This reduces the risk of errors and ensures that prototypes accurately reflect the intended design.

Moreover, CNC precision machining enables functional testing of prototypes under realistic conditions. Components can be produced to the same standards as final production parts, allowing engineers to evaluate performance, durability, and compatibility. This rigorous testing helps mitigate potential issues before entering full-scale manufacturing.

Future Trends in CNC Precision Machining

The future of CNC precision machining in industrial prototyping is marked by automation, digital integration, and smarter materials. Emerging technologies, such as AI-driven machining and predictive maintenance, are improving efficiency and reducing downtime. Advanced simulation software allows engineers to anticipate machining challenges and optimize tool paths before production, further enhancing accuracy.

Sustainable manufacturing practices are also influencing CNC precision machining. Innovations in material recycling, energy-efficient machines, and optimized production workflows contribute to environmentally responsible prototyping, aligning with industry demands for sustainability.

Conclusion

CNC precision machining has revolutionized industrial prototyping, offering unmatched accuracy, flexibility, and efficiency. By enabling rapid iteration, material versatility, and complex design execution, it empowers engineers and designers to develop high-quality prototypes that closely resemble final production parts. The integration of CNC machining with other manufacturing technologies and advancements in automation continues to push the boundaries of what is possible in industrial prototyping.

For companies looking to innovate quickly and maintain a competitive edge, CNC precision machining is not just a tool—it is an essential part of the product development process. Its ability to deliver precision, reliability, and speed ensures that prototypes serve as accurate representations of final products, reducing risks and accelerating time-to-market. As industries continue to evolve, CNC precision machining will remain a driving force behind efficient, high-quality prototyping and manufacturing.